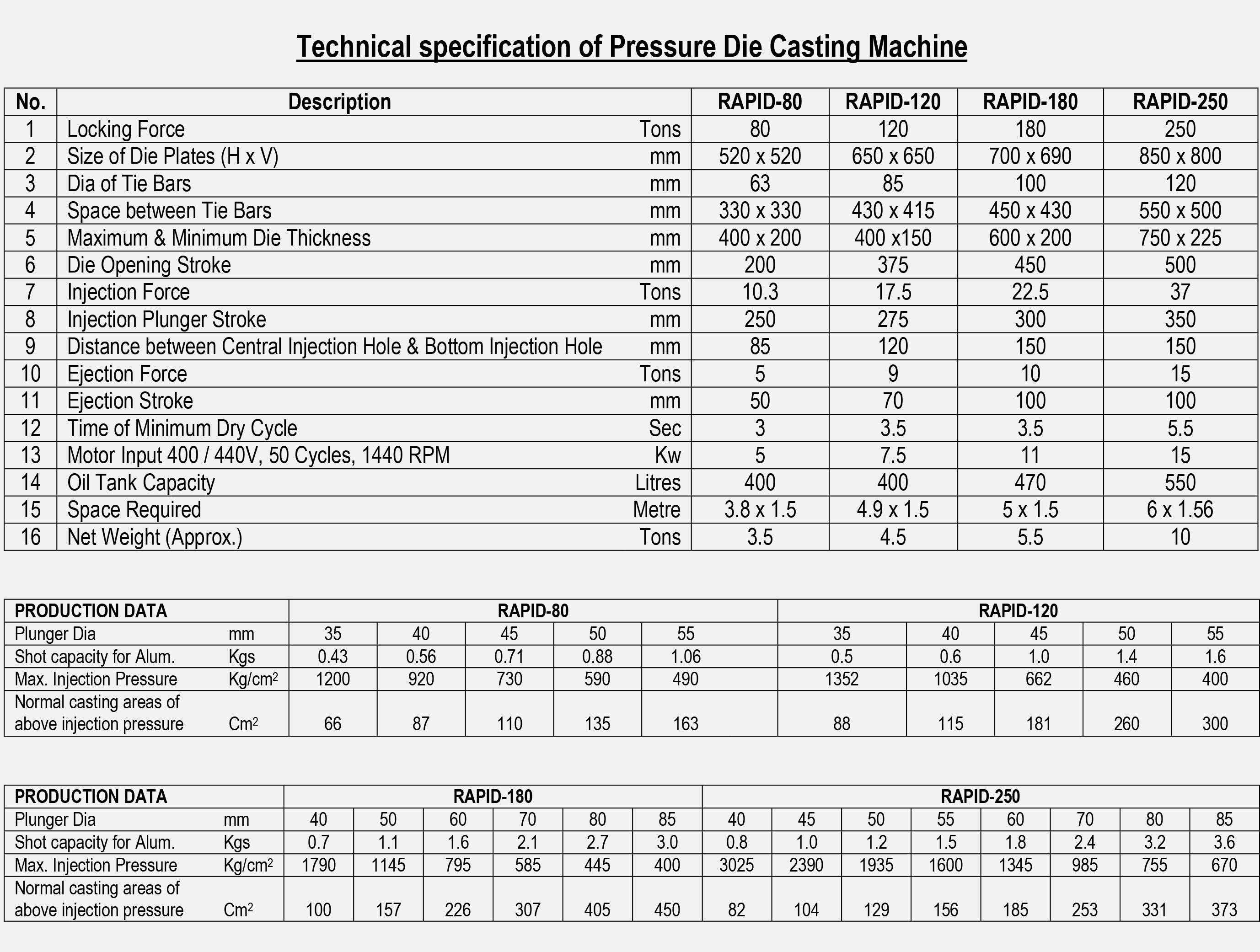

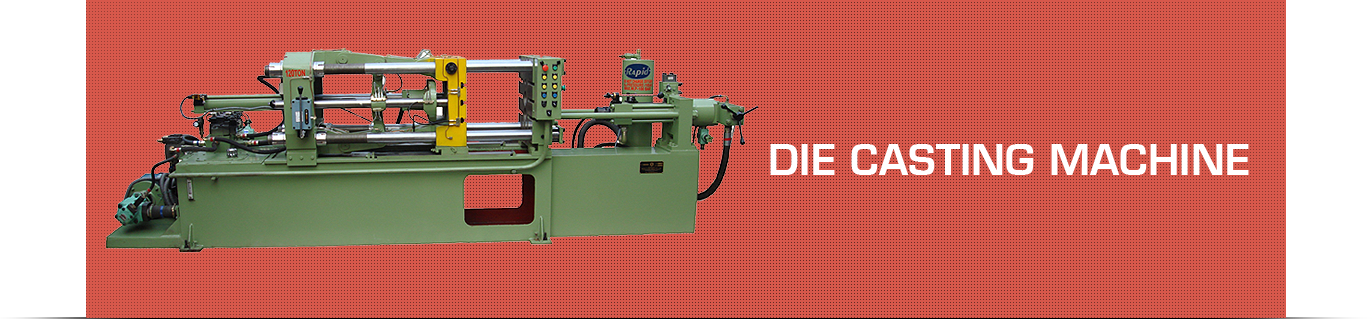

Die Casting Machine

Introduction of Die Casting Machine

RAPID Cold Chamber Pressure Die-Casting Machines are manufactured under the guidance of qualified and highly experienced engineers. The machines are built with best quality materials and components.

These are available in four models, i.e. 80, 120, 180 & 250 Ton Capacity. The Machine can be operated on manual as well as semi-automatic basis and best suited for mass production of Die-Cast Components (such as Automobile, Electricals, Toys, Measuring Instruments & Home Appliances) for casting of Aluminium, Zinc & its alloys.

MACHINE BASE: Machine base is extra strong structural construction, which supports the injection system on its extension. Part of the base is attached with oil reservoir to accommodate a good quantity of hydraulic oil and is provided with oil gauge and digital thermometer.

DIE LOCKING MECHANISM: Die locking is effected by means of hydraulic and sturdy toggle mechanism exerting an evenly distributed force over the faces of the dies. The die space between the two die mounting plates is adjustable to suit any die thickness as mentioned in the table. The die locking mechanism is four Hard Chrome plated Tie Bars running on linear bushes for smooth movement of moveable die, water cooling arrangement for die plate & fix platen.

INJECTION: Injection Plunger is hydraulically operated and powered with high-pressure accumulator to give fast sequence of shots. The provision of lower injection and central injection is provided.

EJECTION: A separate Ejection Cylinder for ejecting the casting from the die cavity has been provided.

HEAT EXCHANGER: A shell and tube type condenser is provided to prevent the overheating of oil and mould. It can be cleaned very easily after removing both the side covers.

HYDRAULIC SYSTEM: Hydraulic system consists of double vane pump, relief valve, flow control valve, accumulator, unloading valve and solenoid operated direction control valves. All controls are fitted on single manifold to avoid complicated tubing.

ELECTRICAL SYSTEM: All electricals consists of standard make switchgears, relays, contactors, etc. are housed in a central metal cabinet. An operating control box (mounted on the fixed die plate) located at the operating position ensures full safety of operation. An emergency stop switch also provided to ensure instantaneous stopping of all motion in case of need.

Features of Die Casting Machine

- Three Stage Injection System (for best efficiency). First stage for slow alloy transfer, second stage for injection of material & finally third stage for squeezing of metal in the mould in semi solidification condition.

- The Rapid Machine is built with a very unique design. It has got a piston type accumulator, which is very long life system with very rare recharging of Nitrogen & negligible breakdowns on account of gas charging in comparison to bladder type accumulator used by other Pressure Die-Casting Machine manufacturers.

- The floating piston in Rapid Pressure Die Casting Machines acts as a barrier between Nitrogen and Oil Chamber. This floating piston works as a damper and due to additional gravitational force, it enhances the injection force which ultimately improves the job quality.

- Only Rapid machines are designed on low working pressure with larger piston areas which improves the tonnage capacity and reduces the strain and ultimately enhances the life of seals, pipelines and joints, therefore the chances of leakage of oil is minimized.

- All Pistons Rods, Tie Rods are duly ground and hard chrome plated and are made with larger diameter to provide the robustness to Rapid machine.

- The design of Rapid Pressure Die Casting Machines consists of High Pressure and Low Pressure Tandem Pump to reduce the Horse Power of the Motor. The running cost of the machine is reduced drastically. A lower connected load serves the purpose.

- Automatic unloading system to reduce the power consumption during idling, again a saving of energy resulting higher profits by using Rapid machine.

- All the seals used are standard high quality PU grade (Foreign make) having very good service life.

- All pipeline joints where replacement of parts is anticipated are provided with ferrule type fittings so that the breakdown period is minimized and replacement of worn out parts becomes very convenient during maintenance.

- The casting of platens are duly seasoned before machining to avoid deformations during machining at manufacturing end and under usage at customers end.

- The platens casted are made from special & tested graded alloy steel in extra ordinary thickness to give a deflection free long lasting service life.

- The moving platen is provided with an adjustable double taper Phosphorus Bronze foot pad slide, which maintains the alignment at the tie rods, ultimately giving smooth long working life to tie bar rods & guide bushes.

- The alignment of the injection cylinder is maintained within 0.2mm for enhanced sleeve & plunger life, which ultimately gives higher profits.

- Parallelism between the platens are maintained within 0.2mm for long life of the mould & negligible flashing of alloy during casting operation.

- All toggle pins used are hardened ground and toggle bores are roller burnished for long life working with maximum accuracy.

- Robust Bell housing is provided between motor & tandem pump to give best alignment at the coupling for maintenance free running of motor & pump.

- Highly reputed centralised lubrication system with sturdy fitting is provided for smooth running of major moving parts.

Optional Machine Accessories

- PLC in lieu of Electric Control Panel

- Necessary core pulling arrangement

- Automatic centralized lubrication system

- Auto Ladler

- Auto Plunger Lubricator

- Auto Die Coat Sprayer

Auto Ladle Unit

Auto Plunger Lubricator